An unusually large brass and iron clockmaker's uprighting tool, stamped for Robert North and Sons, Bushey, probably late 19th/early 20th century The 10 inch circular cast brass stage fitted with three steel work clamping arms incorporating knurled locking screws and substantial vertical brass tube for a lower pump centring arbor, the top with shaped limb to carry the upper arbor, on three down-curved cast supports with angled pad feet drilled for fixing to a bench, the stage bearing stamp Rob’t North & Sons, 18 Rudolph Road, BUSHEY HERTS height of frame 53cm (21ins) high; with two other uprighting tools, both probably Swiss, circa 1900, 23cm (9ins) and 15cm (6ins) high respectively, (3). The firm Robert North and Sons of Bushey, Hertfordshire appear to have been instrument and possibly machinery suppliers most likely established during the first quarter of 20th century; and are still in business today. A rare one-minute torpedo timer attributed to Charles Frodsham but retailed by Robert North and Sons (dating to circa 1944) was sold in these rooms on September 20th 2017 (lot 313).Uprighting tools were mainly used to ensure perpendicular alignment of wheel pivots between clock or watch movement plates during the rebushing process. The basic standard design can be seen in a catalogue published by Berthoud in 1763 which is reproduced in Crom, Theodore R. Horological Shop Tools 1700-1900 on page 100 (figure 149). It is most probable that the principal item in the current lot is of Swiss manufacture and was either retailed by Robert North or used in their workshops.

We found 82038 price guide item(s) matching your search

There are 82038 lots that match your search criteria. Subscribe now to get instant access to the full price guide service.

Click here to subscribe- List

- Grid

-

82038 item(s)/page

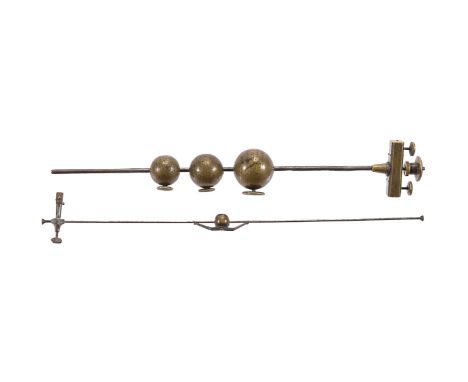

Two fusee adjusting rods, unsigned, probably English, first half of the 19th century The first with clamp incorporating three thumb screws at one end of the steel rod fitted with a set of three brass graduated spherical weights each with thumbscrew for locking onto the shaft, 33cm (13ins) long; the second with clamp employing a single thumbscrew set onto a sliding mount with further thumbscrew for locking onto the shaft further applied with small brass spherical weight incorporating friction spring, 33.5 (13.25ins) long, (2). Fusee adjusting rods are designed to assist in setting the tension of a mainspring to its optimum range to provide equal torque to the wheel train throughout the range of a fusee gear. A description of how such tools were used can be found in Crom, Theodore R. Horological Shop Tools 1700-1900 on pages 474-75.

An English steel and brass clockmaker's mandrel, unsigned, probably Lancashire, mid 19th century The 4.5 inch circular faceplate fitted with three adjustable ‘dog teeth’ work clamps applied to spindle pivoted within brass elongated U frame via adjustable end-pivot and driven by offset six-spoke hand wheel mounted via depth adjusting slide on a curved steel arm, the opposing end with integral brass bar bed fitted with an adjustable tool rest, 30.5cm (12ins) long. A similar albeit smaller mandrel stamped ‘John ALCOCK’ is illustrated in Crom, Theodore R. Horological Shop Tools 1700-1900 on page 529 (Figure 1051).

An important George II/III mahogany domestic regulator, Henry Hindley, York, mid 18th century The substantial eight-day movement with plates measuring 8 by 6.75 inches united by four typical Hindley pattern double baluster pillars, the trains with six-spoke wheel crossings and high pinion count throughout, the going train with deadbeat escapement set low between the plates regulated by seconds pendulum with heavy lenticular bob and long crutch, with bolt-and-shutter maintaining power activated by a line connected to a crossed-out pulley segment positioned behind the dial engaging with a system of sprung levers to apply torque to the centre wheel, the gravity-fed rack striking train sounding the hours on a large bell mounted above the plates via hammer cocked on the backplate against large reverse ‘L’ shaped combined spring and stop, with typical Hindley system of trip-hour repeat incorporating substantial sprung steel lever engaging with the strike lifting detent via wheel on the backplate applied with a pair of pins configured to allow lever to operate in either direction, the calendar work advanced via a pump and system of sprung levers connected to a crank on the calendar wheel set behind the dial, the movement fitted with slide-in dust shutters to sides and top dressing up to the rear of the dial plate,the 12 inch brass break-arch dial with subsidiary seconds dial to the finely matted centre within fine narrow silvered Roman numeral chapter ring with Arabic five minutes to outer track and signed Hen’y Hindley, York to lower margin, with pierced steel hands and rococo scroll cast spandrels to angles beneath arch centred with calendar dial flanked by conforming mounts, the case with giltwood ball finial to the generous ogee-shaped caddy surmount over box frieze applied with crisply moulded swan neck pediment and architectural break-arch mouldings over the hinged glazed dial aperture flanked by substantial Doric columns, the sides with blind break-arch panel doors and conforming full columns to the rear, the trunk with ogee throat moulding over shaped-top caddy moulded door flanked by fluted quarter columns to front angle, on plinth base with cavetto top moulding and bracket feet, 251cm (95ins) high excluding finial; 251.5cm (99ins) high overall. Henry Hindley was born in Great Harwood, near Blackburn, Lancashire 1699, little is known about his early life, however by the mid 1720’s he was making clocks in Wigan where he repaired the church clock in 1726. Hindley moved with his young family (including his son, Joseph born 1728) to the prosperous city of York where, after making clocks for the Mansion House and Guildhall, he gained his Freedom of the city in 1732. Hindley s talents were such that he equipped his workshop with tools of his own design including an important dividing and wheel cutting engine, a screw cutting lathe and a fusee engine. As well as domestic clocks Hindley received commissions for several turret clocks including York Minster and supplied a range of scientific instruments including two important equatorial telescopes for the Duke of Norfolk and William Constable. By the 1760 s Hindley s health had deteriorated to the extent that an ever increasing proportion of the business was handled by his son Joseph. Henry died in 1771 with his son and successor Joseph unfortunately dying just three years later in 1774, before he had had the opportunity to stamp his own mark on the family firm. Hindley s work demonstrates a highly inventive exacting approach with each clock perhaps varying in some way to its predecessor ensuring constant refinement in design and layout. The quality of the finish of his work is generally exceptional being comparable to the very best London makers of the period which is why many collector’s refer to Hindley as the ‘Tompion of the North’. The movement of the current lot is no exception being a particularly fine example of Hindley’s work exhibiting inventive details such as the cranked pumping mechanism for the calendar dial, gravity fed rack striking, concealed clicks to the barrels and combined hammer spring and stop. The bolt-and-shutter maintaining power is beautifully executed and the movement exhibits the rare feature of having brass dust shutters fitted. The winding key present with the clock is suitably finely made and is most probably original.The case is also of the finest quality and as equally distinctive as the movement with the hood in particular featuring fine crisp mouldings and generous architecturally correct Doric columns. Unusually the hood is fixed integral to the trunk hence the movement and dial have to be inserted into the case via the dial aperture, the doors to the sides then allow the pendulum to be hung and the lines for the trip repeat and maintaining power connected. The reason for this arrangement is not obvious but it seems that Hindley sought to make the movement difficult to access/examine on purpose. From this it is perhaps appropriate to speculate that the current lot could have been supplied for a semi-public environment requiring the design to incorporate ‘anti-tampering’ features which would have served to reduce the chances of others copying some Hindley’s innovative features as well as preventing inexperienced individuals making unwelcome adjustments. Indeed if this is the case then it is possible that Hindley himself was initially contracted to tend to the clock. The inside of the trunk door is applied with a paper label inscribed in ink Sep’r 68 and Nov 30th 87 G.W. these probably note/record subsequent servicing of the clock. Indeed the visible positioning of this information also supports the possibility that the current lot was originally supplied for a semi-public environment where such information would need to be visible to ensure that the clock is correctly maintained.

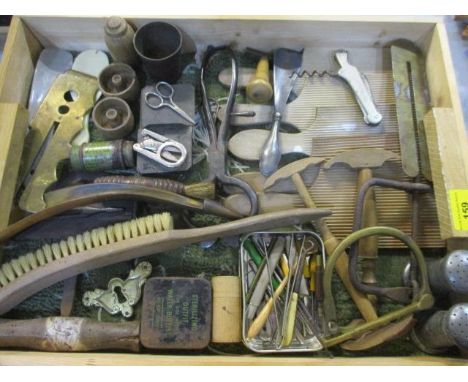

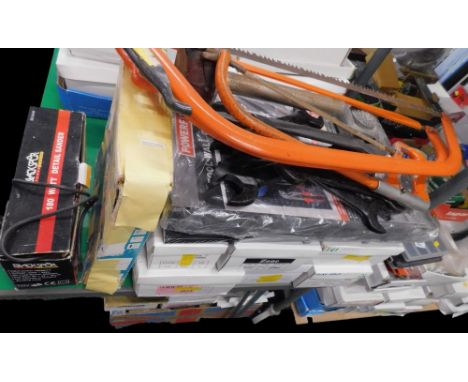

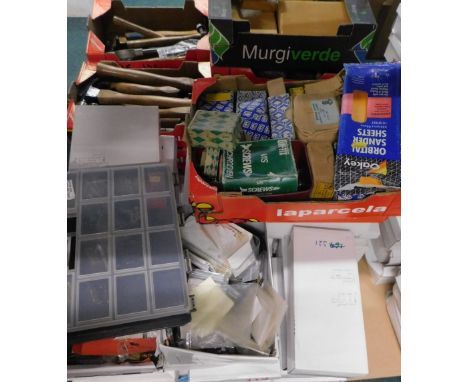

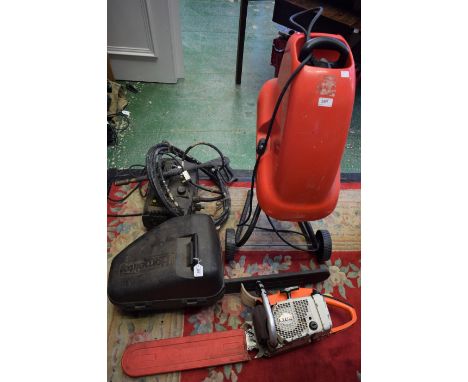

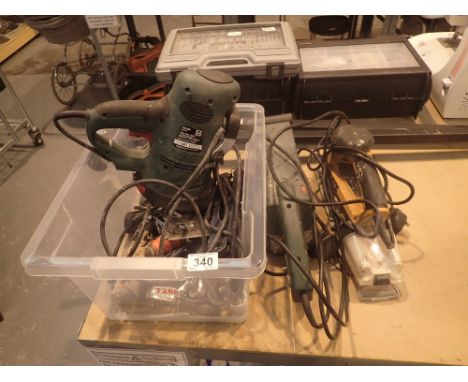

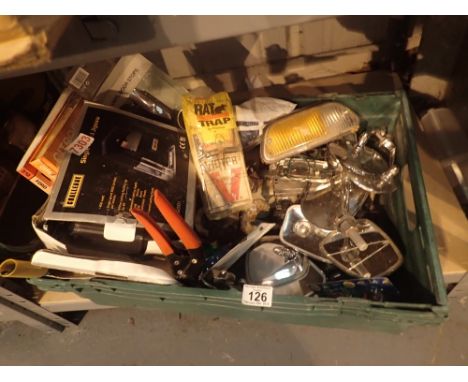

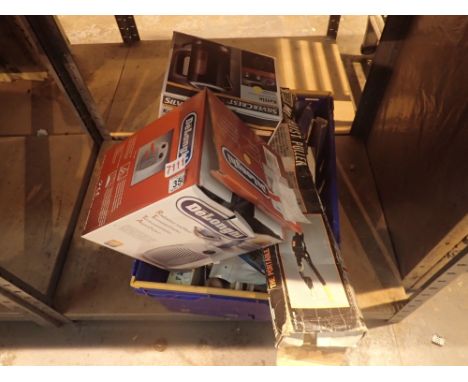

Selection of hand tools sockets etc orbital and band sander Worx sander and pair of roof rack bars CONDITION REPORT: The electrical items included in this lot have been PAT tested and have PASSED. This test means that they are electrically sound and does not confirm that they are in working order. WE DO NOT CONFIRM WHETHER ITEMS ARE WORKING AND ARE THEREFORE SOLD AS SEEN.

-

82038 item(s)/page